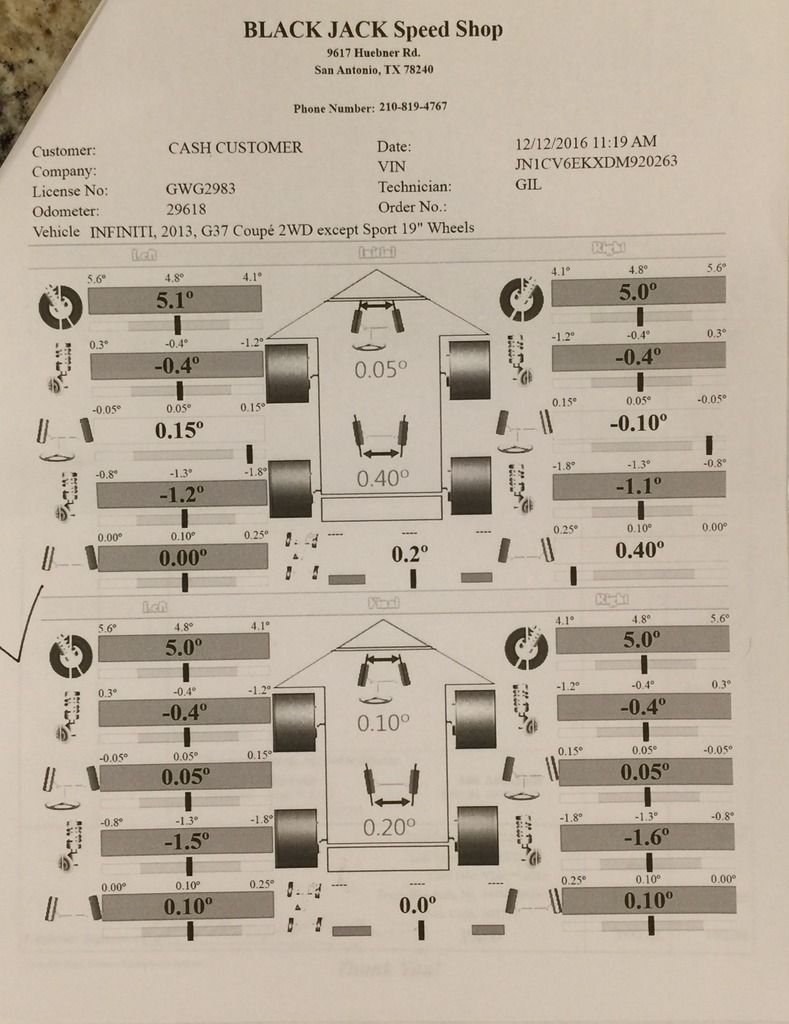

Alignment was a success yesterday and I have very conservative numbers all around. See alignment sheet below. I may have them add a bit more negative camber but I'd like to go without replacing tires once a year. I drive between 8-10K per year these days, mostly highway. New wheels/tires going on tomorrow.

The loud clunk persists and I don't think they took a look at it. Doesn't happen over bumps while driving, it's sharp, squared-edge impacts that cause it. Like the lip of a driveway. Sounds really bad (metallic clunk and a bit of a metallic squeak) so I decided go out, pull the front wheels off, yank out the dampers, and re-torque the SPC arms and make sure everything is kosher. I didn't reuse the little bushing that comes with the stock upper control arms, may throw those in too, dunno. Directions don't really do you any good in that regard.

Once the new, slightly taller tires are on, I should theoretically be able to lower the car a few mm lower and be at the same height. Taking measurements today prior to tomorrow's tire change.

I'm also going to go out later, after fixing whatever noise is being created, to see if the new rear alignment numbers help in the traction dept.

Here's the alignment sheet, current specs are on the bottom (checkmark next to it):

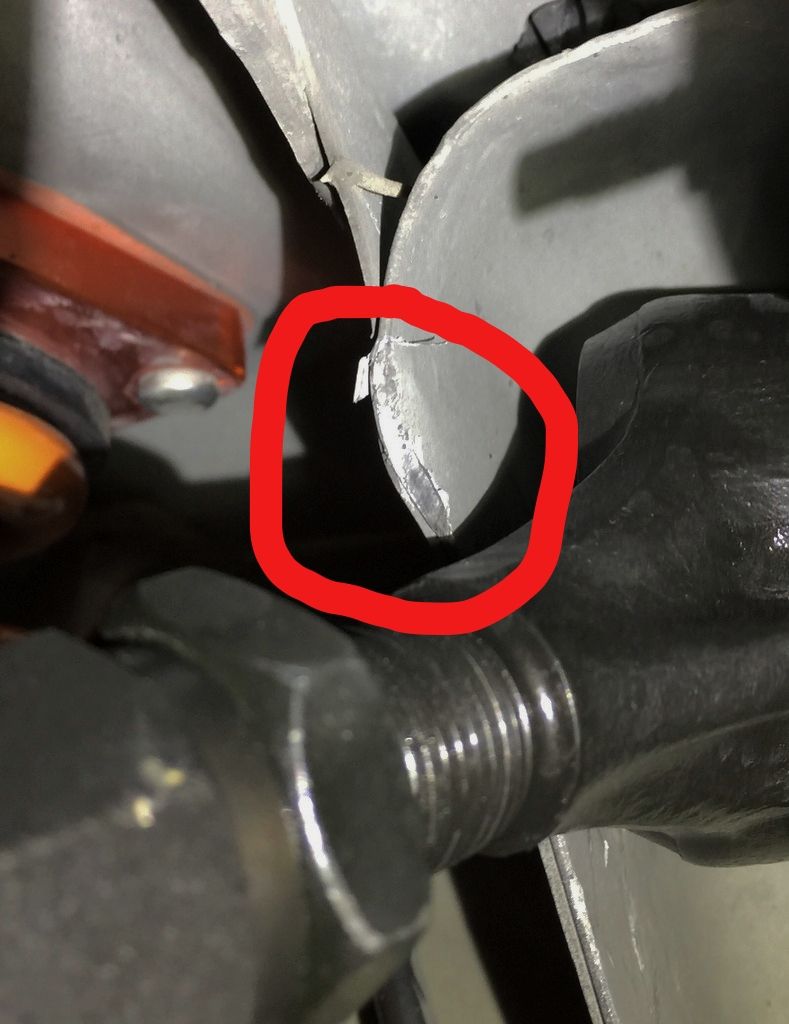

And I found the culprit for the loud thunk/metallic squeak/grind. It's the leading bushing/forging closest to the nose of the car.

For those who've changed out their upper control arms, you'll understand. The upper arm is an A arm. The two inboard forgings with bearings connect to the car via a bolt. The forging/bearing basically sits in between the strut bulkhead on one side and sheetmetal on the other. The front forging, one closest to the nose of the car, is hitting the sheetmetal. It's dented it in already.

Now the instructions explicitly say to install either forging end so it's parallel to the sheetmetal/bulkhead. You don't want the bearing sitting at an angle. I did this when I installed them but it looks like the shop that did the alignment did not because they were very much skewed when I took the wheel off. It's easy to skew them while making adjustments.

What I did is loosen the back locking nut on the SPC arms and loosen the bolts holding them to the car. I had a 17mm open end wrench that was the right width and I stuck it in one side of the forging/bearing which kept it parallel to the sheetmetal. I then tightened the locking nut again on the SPC arm. Easy enough. I later found the SPC video below which said to do the same thing.

I did have to take the entire shock out. It's much easier to get everything right and due to the tall adjustment knob on the Aragostas, I couldn't "load" the arm and still have the shock out of the way enough to get a torque wrench in there without pinning the adjuster agains the top of the strut tower. Once removed, I then loaded the assembly by jacking up underneath the brake disk and pushing everything up. I then torqued the bolts and reinstalled everything.

I did a quick run up and down the driveway and didn't hear anything. I'll need to take the car out to see if it solved the issue. Personally, I don't think it did and I'm going to contact SPC to see if they have any insight (update below).

Pics.

You can see the wrench on the left side of the forging/bearing keeping it parallel. This is on the passenger's side, rear forging.

Here's a shot of the front forging/bearing, passenger's side, closest to the front of the car. You can see where the sheetmetal has been pushed out in an arc as the forging is pushed up. This is with the arm pushed fairly far up.

Here's a shot of the damage, with the arm all the way down (decompressed). This is before I took everything out to make adjustments and you can sort of see how the end of the control arm, the forging, is skewed and not parallel to the sheetmetal.

It seems like there's more clearance on the rear side of the control arm. It did this on both sides. I measured the length of each end and there's no difference.

Just found there's a video on the SPC site, with installation on a G35 but it's pretty much the same except we have a different pinch bolt design.

https://www.youtube.com/embed/Lf55rRgBSZY

Ok just got off the phone with SPC. They're coming out with an updated FAQ related to this issue. Essentially it's a non-issue depending on how you look at it. He said straightening the forgings and making sure they're parallel to the sheetmetal alleviates it most of the time but it depends on your caster setting and it can interfere on higher settings. They're also seeing some interference on vehicles that are really lowered (mine isn't) in that spot. He basically said to bend the metal back there at the top back a bit and problem solved.

Ultimately not the answer I'd like to hear and while it'll not really cause any long-term issues I'd rather not have this issue in the first place. As minor as it is (and it's a quick fix if you know to look for it) just take it into consideration before purchasing or installing. It's not enough of an issue, as long as it doesn't further deform or cause any abnormal noises, for me to swap them out to say the Voodoo or SPL.

Hope that helps!