Hi everyone!

Mike here at www. NonStopTuning .com

I wanted to stop by to say hello and share our new 370Z VQ37HR dyno testing and results with you!

MUCH MORE INFO HERE:

http://www.nonstoptuning.rpmware.com...i-1829854.aspx

The new 09 370Z HR and the 08-09 350Z HR engine share the same pulleys, so we decided to take a local car here in Houston TX out for some dyno testing...

http://nonstoptuningusa.com/2014/04/...-dyno-testing/

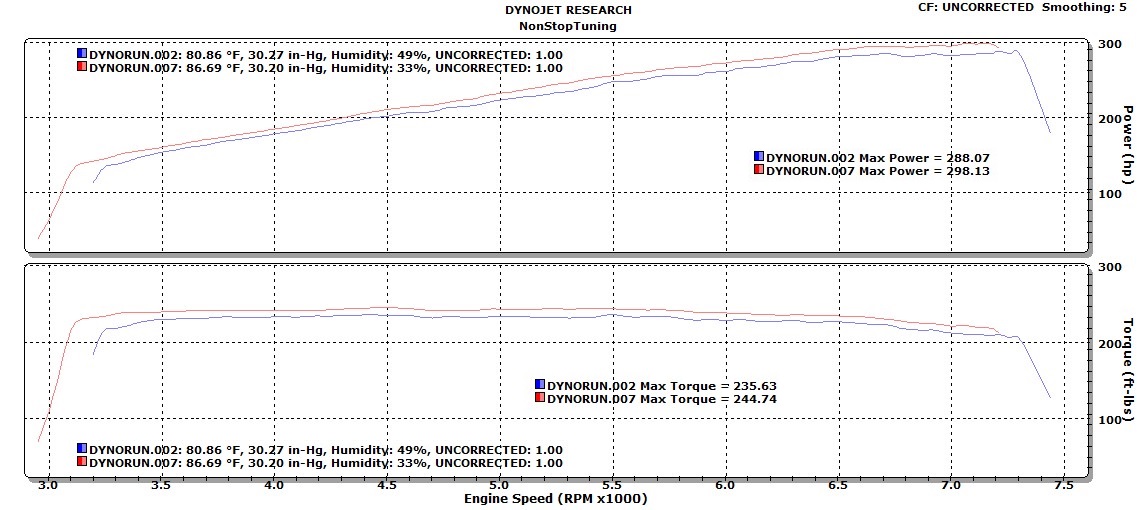

The guys at carboy in Houston did the professional install and ran the dynojet for us. The gains are quite noticeable as shown on the dyno chart bellow. HP & TQ delivery, throttle response, fuel economy, and overall daily driving is enhanced due to the great weight reduction and the small, very conservative, amount of underdriving.

As you look at the charts you can see that the increase in power is shown from 0 all the way to redline (7200 rpm). Max power increased by roughly 5whp and max torque increased by roughly 6wtq. It is important to point out that the gains are even better in the mid (4000 - 5000rpm) range... gains here are roughly 10whp and 12wtq. NO OTHER $200 kit or any bolt-on mod will provide such gains!!!!

All dynos were ran on the same dyno, on the same day, with NO OTHER modifications, adjustments, or changes made. These numbers are 100% legitimate and repeatable.

The NST Kit includes a 10% Underdrive Crank Pulley along with a 10% Overdrive (faster) Alternator Pulley. This means that the alternator will run at OEM speeds when the NST kit is used. Extra power, torque, and response... no need to worry about a weak battery, dimming lights, or poor a/c performance at idle.

Anyone who may be interested in availability, pricing, and more info can visit...

http://www.nonstoptuning.rpmware.com...i-1829854.aspx

The original test car and the owner's comments can be found here...

NonStopTuning 350Z/370Z HR Pulley Kit Installation, Dynos, Info - USimports.org

Many thanks everyone, good luck and have fun with all your projects!

ADDED TO UPDATE INFO ON THIS THREAD...

This one deserves an entire book, but here goes...

Q. Will NST Pulleys lead to premature engine failure?

I cover this topic at least several times a month but I don't mind, I understand that your cars are a very large investment for all of you and I prefer that you be intelligent and informed about all your modifications. So here we go again... Please take a few minutes to read everything I have posted here, as I worked hard on trying to give you a good explanation on the topic...

In the past many engines were externally balanced. There was an external balancer attached to the outside of the engine, on the crank snout, used to balance the engine externally. The crank pulley in such engines would then be attached to this balancer. Removal of this balancer is a bad idea. These balancers were most often used on large (8 cyl) V shaped engines of the domestic muscle car era.

Take a look at any modern (1980s and beyond) Honda, Toyota, Nissan, or other japanese engines and you will find no such balancer. These engines are all internally balanced, and this process has improved even further since the late 1990s. So the topic of a BALANCER does not apply here.

What you will find on many modern engines is a harmonic damper. This is a small rubber band literally less than 2mm (less than 1/8th of an inch thick) that is built into the crank pulley. OEM crank pulleys are often called DAMPERS. Try placing an order for a crank pulley at your dealer and your invoice will read damper. This rubber is used to absorb something called NVH, noise/vibration/harshness. Suffice it to say, this rubber is actually not very good at performing its intended purpose after as little as a few thousand miles. What happens to rubber after a couple years of humidity, weather, snow, rain, etc? It often becomes brittle, hard, and crunchy. Can something with these properties actually absorb vibrations very well?

Many many NST customers, including people on your own forums, have reported smoother running engines with NST pulleys. Especially at idle. How is this possible if the rubber is such a vital and super important piece? Perhaps the rubber is not as important as it is cracked up to be?!

Furthermore....

On the topic of the rubber damper, engine vibrations, or possible threats resulting from elimination of this rubber piece...

On a relatively understressed motor with bolt-ons or low amounts of boost like what most of the people on this forum probably run, a solid pulley will not have any life threatening consequences. The factory pulley with a 2mm (less than a 1/8th inch) damper is primarily there for wide band NVH (noise vibration harshness) suppression from the engine and driveline. Removing the damper and replacing it with a solid pulley may lead to minor additional NVH but will not harm the engine. In fact, most people claim their engines seem to run smoother with NST pulleys.

The engineering reasons are that most modern engines have a short, strong crank with, a relatively high natural frequency. The dangerous second harmonic that can cause damage occurs at an rpm that this sort of engine will never see, in the area above 10,000 rpm. Even the stock damper is not tuned for attenuation at this sort of rpm so the argument is somewhat of a moot point.

Now weak engines that are pushing the limit with LOTS of revs, wimpy cranks, super long strokes, lots of boost and dwelling in the upper rpm ranges for long periods of time can benefit from a damper designed to deal with this sort of operation but our engine is not like this, and probably very few people with this motor on this forum push the envelope that hard. How many 500HP + 12,000RPM motors do we have on these forums?

As far as I can tell, our engine has a strong and stiff bottom end that is well built for our intended use. It has an internally balanced crankshaft which is less like to break due to torsional vibration.

There are a lot of Honda, Toyota, and Nissan guys who use underdrive crank pulleys in road racing series like NASA or SCCA. Road racing is much more punishing on an engine than other motorsports. The engine is subjected to run times lasting roughly 30 minutes with the engine always in the upper ranges of its rpm limit. One race weekend is the equivalent of hundreds of 1/4 mile passes. These guys would not use NST pulleys if they were not reliable.

NST sponsors the first ever wheel to wheel Scion tC NASA Road Race car. The same car is also very competitive in the Grand Am and World Challenge series and has factory backing from Toyota, Scion, and TRD. This car has been using pulleys from NST with great results since day one.

NST has sponsored several drift cars participating in the professional US drift series, Fromula Drift and Xtreme Drift Circuit. Several of our cars have also competed in D1 Grand Prix USA and the NOPI Drift series. (I've posted numerous photos of these cars here on this forum and on our website blog.) To make things better, NST products are also used in autocross, time attack, and drag cars. These cars have been using NST pulleys with no issues of any kind for the past few seasons.

We could go on and on...

Is a solid crank pulley harmless to all engines? No it is not. As I said... small, super high reving engines, when modified way past the simple bolt on stages may have problems. These engines reach critical harmonics, past the 10,000 rpm range, an rpm only reached by few RACE engines.

A mildly modded inline six will most likely be fine but one subjected to high rpm (10,000+) for long periods of time (90% of its life) with lots of boost will probably suffer. In this case , the stock balancer/damper is probably not adequate either.

Some of the older american V8 engines are externaly balanced and it is critical not to use a solid hub pulley not designed for these applications, or damage to the engine could result. You will not find solid NST pulleys on our website for such engines.

Our engines and most around here do not fall into the above categories. Rest assured that your engines will not blow up and die or have a reduced life in street and even racing use with these parts.

I would bet that every "expert" that tells you otherwise has little personal, practical, real world experience with the subject; as it applies in your case.

Thanks again everyone, good luck and have fun with all your projects!